Specialising in advanced High Performance Coatings in South Africa, we offer superior protection for demanding industrial applications. Our High Build Fluoropolymer Coatings include HB2002 for acidic and corrosive environments from 100°C to 155°C, and Halar, effective from -76°C to +150°C, providing exceptional chemical and temperature resistance. Additionally, we provide Xylan coatings for reliable non-stick applications, enhancing efficiency and reducing maintenance.

- High Build Fluoropolymer Coatings

- HB2002 T 100 C to 155 C for acidic and corrosive environments.

- Halar 76 C to + 150 C for acidic and corrosive environments.

- Xylan for non stick applications.

APPLICATORS OF HIGH RESISTANT PROTECTIVE COATINGS

HB 2002 T

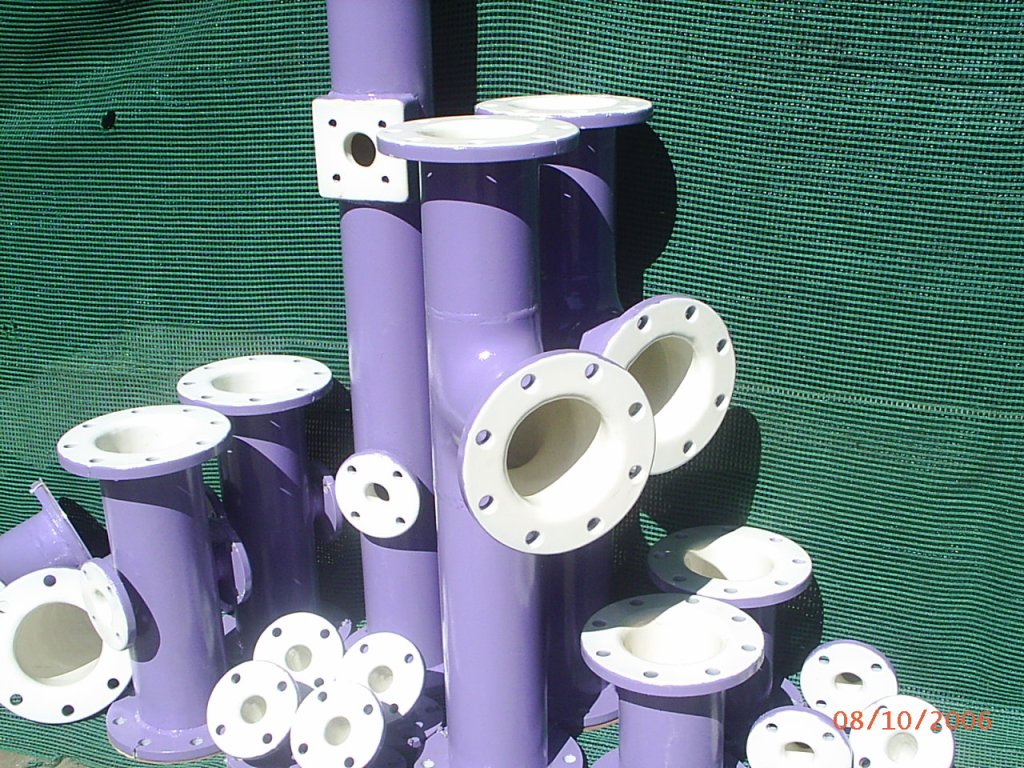

A Fluoropolymer alloy with a controlled blend of virgin E.T.F.E and inert filler designed for extreme corrosion, imp act and excellent abrasion resistance. An excellent all round chemical resistant coating with chemical and stress cracking

resistance to most inorganic acids, bases and solvents close to PTFE requirements, operating under 155°C.

Applied directly on to metal substrates t hat are unde r severe corrosion and erosion conditions in chemical environments with optimum adhesion achieved by blasting to SA 3.

HB 2002 T Typical Applications

Pumps, valves, pipes, fittings, reactors, columns, agitators, dip and sparge pipes, bellows, centrifuges, filters, heat exchangers, fume ducts, tanks etc.

Property comparison

| Properties | HB 2002 T | HALAR ECTFE |

|---|---|---|

| Specific Gravity | 1.70 – 1.75 | 1.68 |

| Max Continuous Service Temperature (°C) | 155 | 150 |

| Low Temperature embrit. (°C) | -100 | -76 |

| Flexural Modulus @ 22°C ASTM D – 790 (MPa) | 1373 | 1690 |

| Tensile Strength at break @ 22°C ASTM D – 638 (MPa) | 44.8 | 48 |

| Hardness Shore | D 67 | D 75 |

| Impact strength Notch Izod @ 25°C (J/m) | No break | No break |

| Water Absorption (%) | 0.03 | < 0.01 |

| Permeability (cm³ (STP) · mm/m² · atm · 24h) O2 @ 25 °C | 71 | 28 |

HB 2002 T

Halar ECTFE