Milling Profiling and turning of plastic materials

Milling processes use rotating multi-point cutters to precisely remove material from a plastic workpiece, creating intricate 2D or 3D shapes, while profiling specifically focuses on generating accurate external or internal contours. In contrast, turning rotates the plastic workpiece against a stationary single-point cutting tool to produce cylindrical or rotationally symmetrical components. Each method is chosen based on the desired geometry and precision required for the plastic part.

P.T.F.E, P.V.D.F, Peek, Polypropylene, H.D.P.E, P.V.C, Nylons Perspex, Polycarbonate, ECT

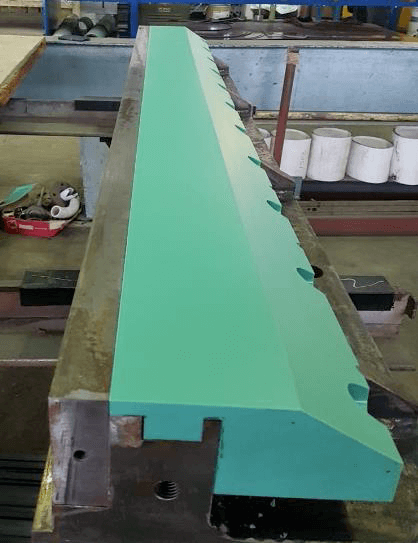

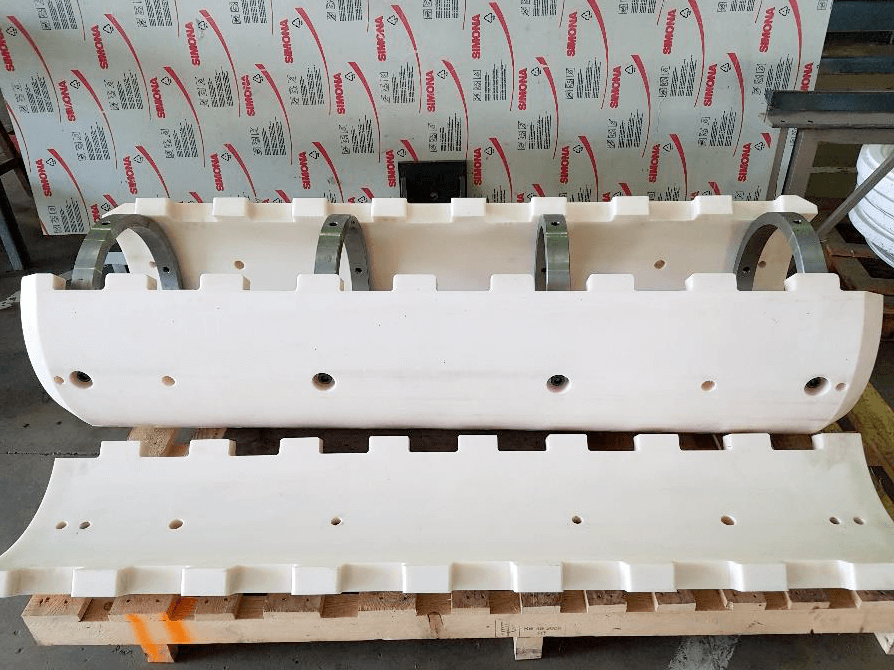

UHMPE Profile

Longer lengths can be accommodated

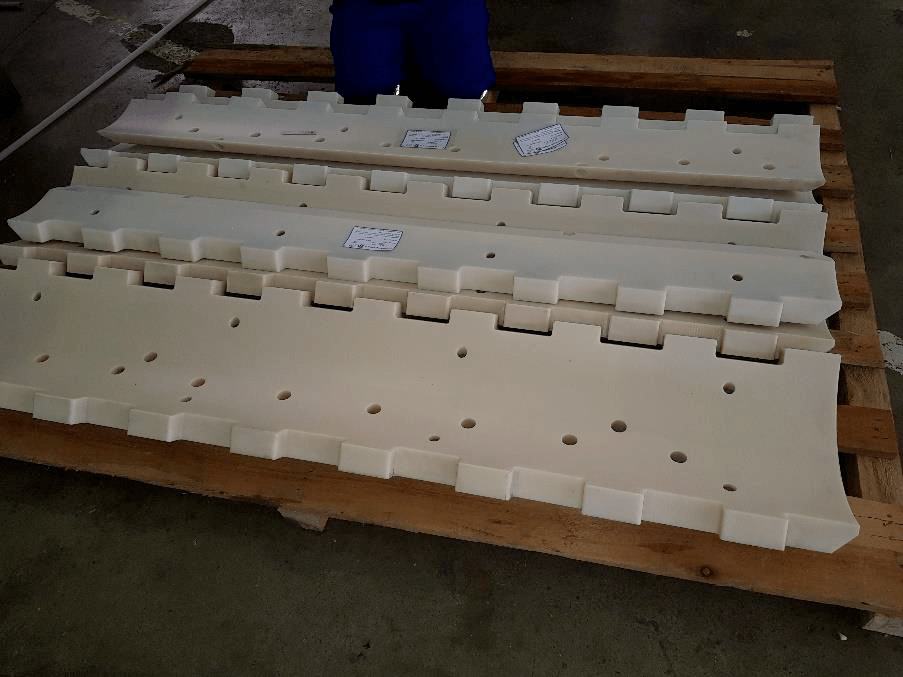

Nylon 6 Segment rings 2 meters long

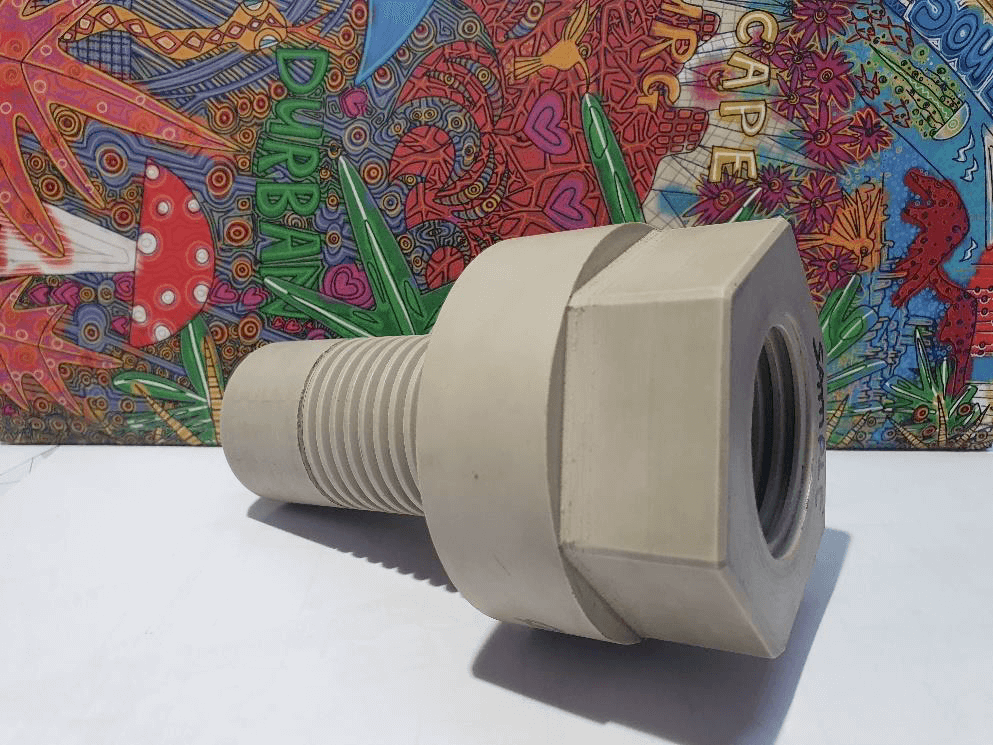

Polypropylene Studs and nuts

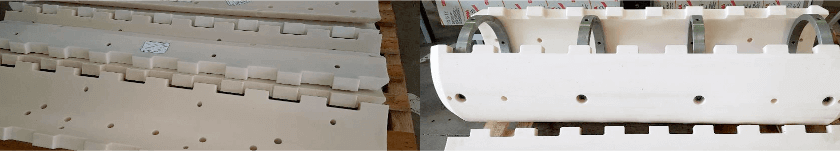

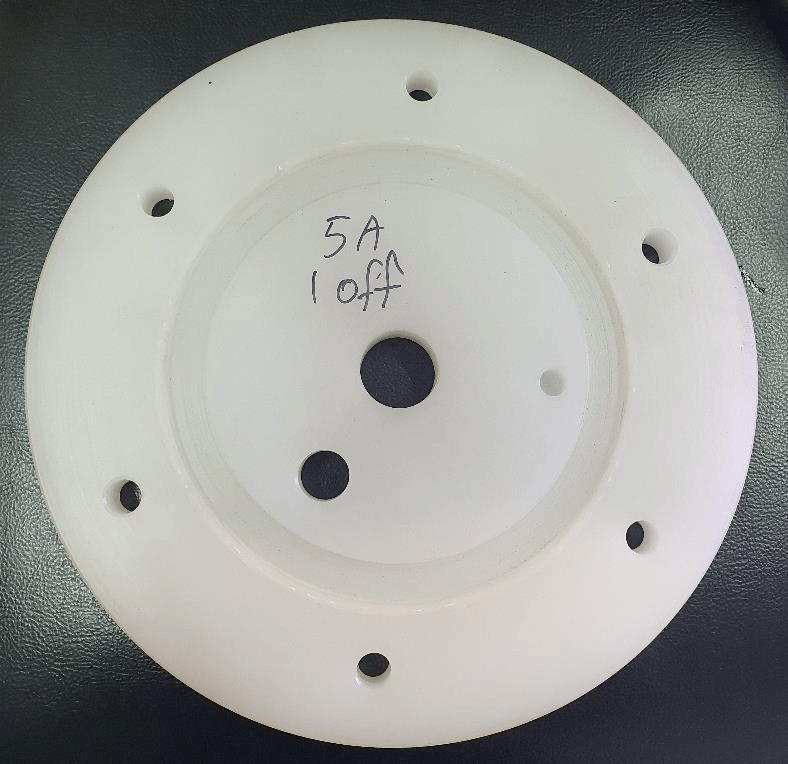

PVDF profile flange

A PVDF profile flange is a connecting component made from Polyvinylidene Fluoride (PVDF), a high-performance fluoropolymer. It’s specifically designed with a “profile” that enables it to be joined to PVDF pipes or equipment, typically through heat fusion welding (like socket or butt fusion) or mechanical connections. These flanges are chosen for their exceptional chemical resistance, high purity, and ability to withstand elevated temperatures and pressures, making them ideal for demanding applications in industries such as chemical processing, pharmaceuticals, and semiconductor manufacturing.

Profile Milling and turning of plastics